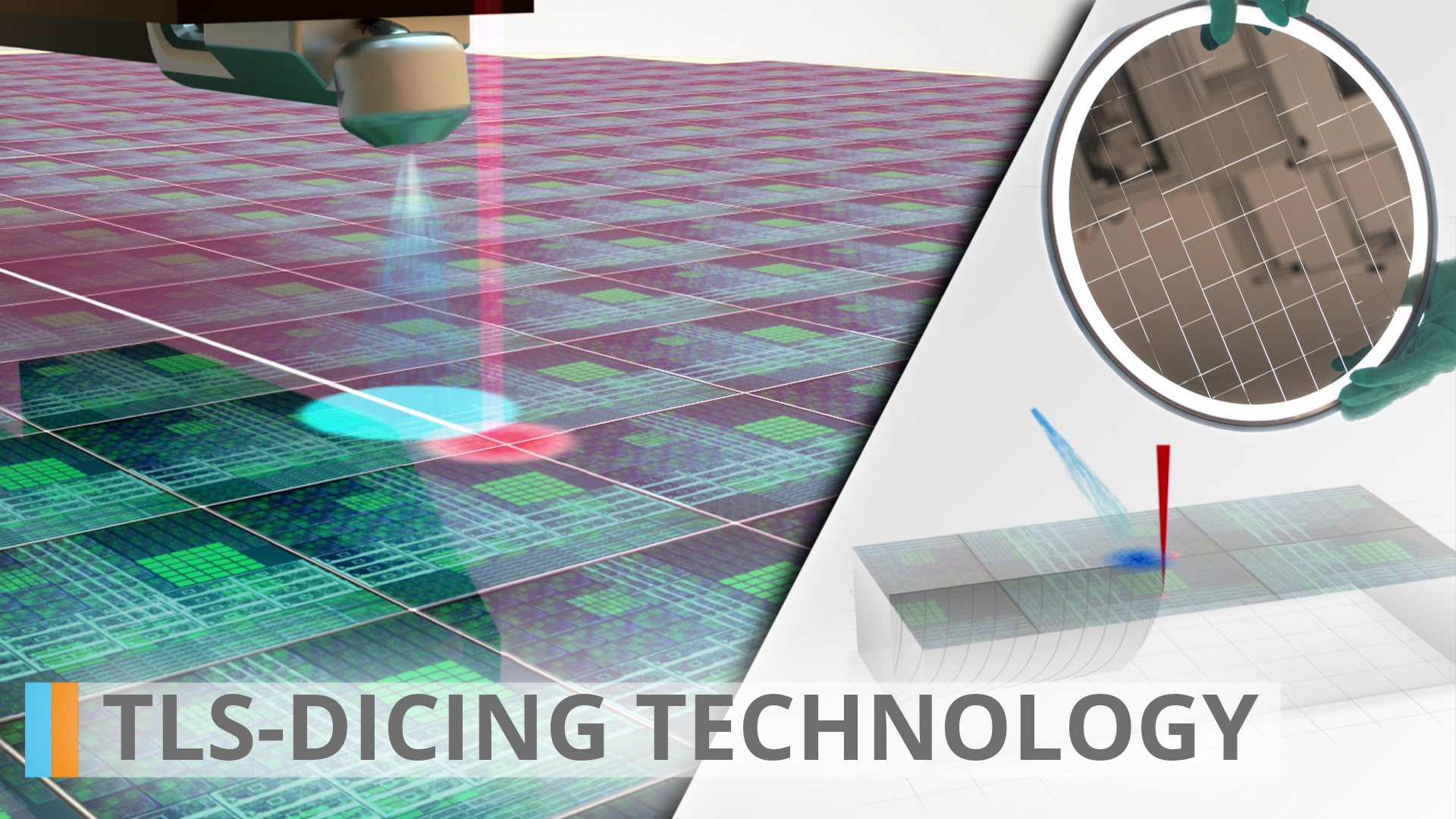

TLS-Dicing®

Enabling Technology for Fast, Clean, and Cost-Effective Wafer Dicing

TLS-Dicing (Thermal Laser Separation) is a unique technology for separating wafers into single chips in semiconductor back-end processing. TLS-Dicing uses thermally induced mechanical stress to separate brittle semiconductor materials, like silicon (Si) and silicon carbide (SiC) wafers.

TLS-Dicing is an ideal solution for wafer dicing that has many advantages compared to competing technologies, such as the currently established method of mechanical sawing as well as laser ablation. These include:

- High separation speed: 300 mm/s

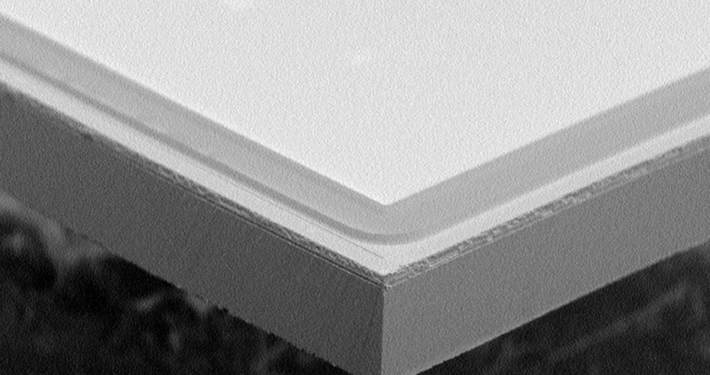

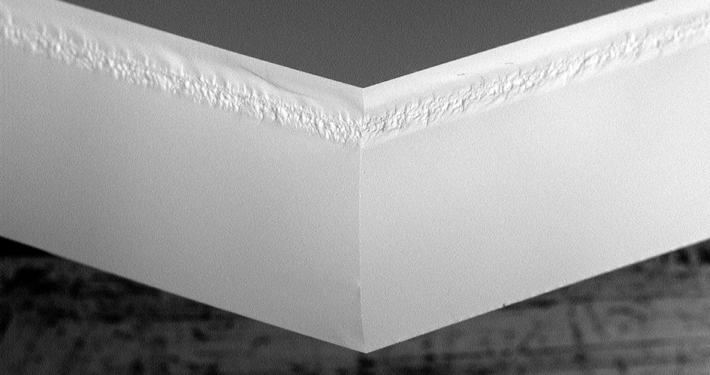

- Very smooth edges (reduces leakage current of diodes)

- Clean and nearly dry process

- Nearly no chipping and micro cracks for less breakage

- Thin back side metal can be separated without damage

- No tool wear

- Lower cost of ownership due to no tool wear and nearly no consumables

- Zero Kerf cleaving process for reduced street width, enabling more die per wafer

- Applicable to larger diameter substrates (e.g. 300 mm)

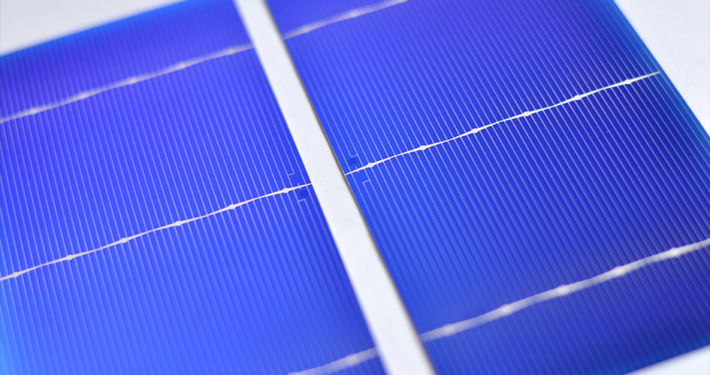

Furthermore, TLS-Dicing is used in photovoltaic industry for separation of standard silicon solar cells into half cells. Compared to conventional separation technologies, TLS-Dicing impresses with its clean, microcrack-free edges. No crystal damage occurs on the separation edge – damage which is otherwise common to date due to the displacement of re-solidified silicon in the ablation region. As opposed to laser cutting, no bulging and no formation of particles occur, because the substrate is merely heated and not vaporized. The mechanical stability of TLS-processed solar cells is significantly greater than conventionally processed solar cells.

Contact:

Please contact our technical sales team for more information.

Frank Richter

Tel: +49 371 40043-222

sales@3d-micromac.com